Fresh and Eco-friendly Food Packaging Ideas

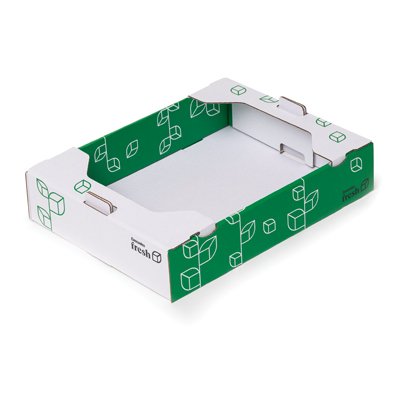

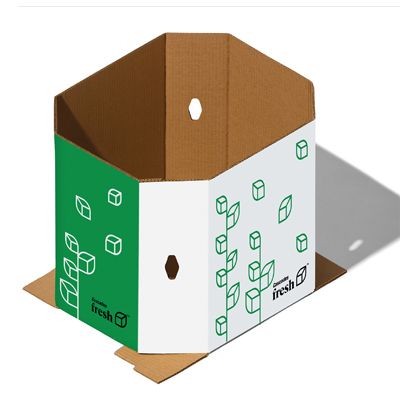

Showcase your products in our high-performance food packaging made from recycled material.

Cascades enhances its line of eco-friendly packaging with an innovative recycled material solution

The 100% recycled PET composition of this tray and its optimized design make it a leading alternative to hard-to-recycle food packaging.

Sustainable packaging isn't just a trend—it's what consumers expect.

Vergers Jean-Yves Boileau & Cascades – Pioneering Sustainable Produce Packaging

Cascades enhances its line of eco-friendly packaging with an innovative recycled material solution

The 100% recycled PET composition of this tray and its optimized design make it a leading alternative to hard-to-recycle food packaging.

Contact us

Contact us to learn more or receive a quote.